Welded wire mesh cages, woven wire cages and expanded metal cages are the most common types of metal security cages. They offer strength, through vision and ventilation, and can be used to store high value goods and equipment as well as hazardous materials.

But what are the differences between welded wire mesh cages, woven wire cages and expanded metal cages?

And how do they affect the level of security offered?

Welded wire cages

You’ll often see metal security cages that are formed from welded wire, which is manufactured by electrically welding metal strands together to form a strong mesh. This is typically seen as a grid pattern.

Wire mesh cages of this type are commonly used to store tools, gas cylinders and valuable goods, and wire mesh can be hot dip galvanized for use in external environments.

However, criminals using the right tools can breach these cages by parting the wire at the welds. This can create an opening large enough for someone to access and steal the contents. This problem is also associated with welded wire fencing.

Woven wire cages

The woven wire mesh used in cages is manufactured by creating an array of intersecting wires. The wires are woven over and under the perpendicular wires to create a metal mesh.

Due to its design, woven wire mesh can be bent without breaking. This means that it can withstand considerable pressure.

However, woven wire can be worked loose and if cuts are made in the mesh, the wires can unravel from each other, creating a security risk. This vulnerability can also affect the security of woven wire fencing.

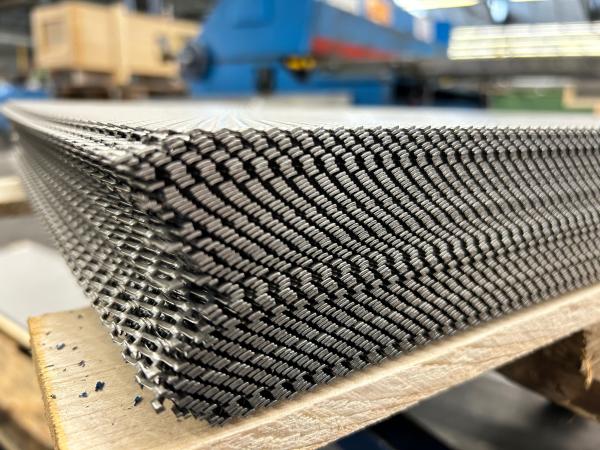

Expanded metal mesh security cages

Expanded metal mesh cages offer an alternative option to welded wire mesh cages.

The expanded metal used in cages is manufactured by simultaneously slitting and stretching steel plate, which is fed through an expansion machine. The mesh cage panels are then cut to the required size.

Expanded metal mesh cages have many key advantages over welded wire mesh cages.

- As the expanded metal panels used in cages are formed from one piece of metal, they are inherently strong.

- There are no welds to target and break with tools such as scissor jacks. An expanded metal cage is therefore much harder to break through than a welded wire mesh cage.

- The uncut knuckles of expanded metal mesh withstand force better than welds or joints, making them high impact resistant. This is particularly important if the cages are being loaded and transported.

- Cutting through expanded metal can generate sharp edges around any breach in the mesh. So, even if a hole is made that is large enough to gain access to the cage contents, it may be dangerous for someone to reach inside!

We offer a range of ExMesh™ modular security cages which provide storage for a range of items. We have three sizes available, often with next day delivery to mainland UK, or can create bespoke cages to your requirements.

Our security cages are easily assembled using the instruction booklet and fixtures provided and can be secured using anchor bolts. All of our cages are hot dip galvanised to EN ISO 1461:2022, offering a low-maintenance corrosion protection, and we offer the option of polyester powder coating in a range of RAL colours. Click here to view our metal security cages.

GBP

GBP