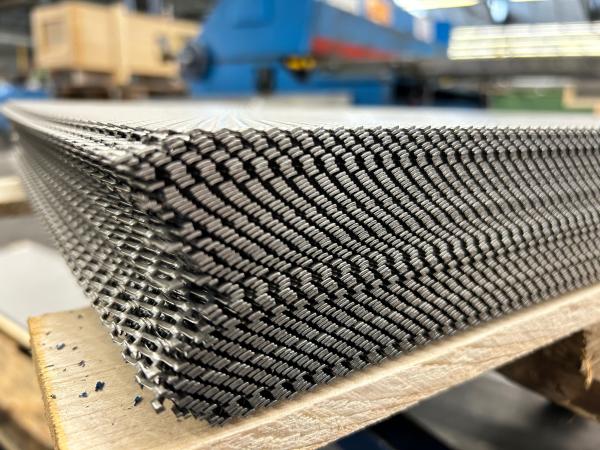

You may call it micro expanded mesh, foil mesh, fine expanded mesh, mini mesh, small mesh… but to us, we call it micromesh and we manufacture it here in Hartlepool for uses across the process industries.

What is micromesh and why is it beneficial in chemical processing?

Manufactured by a process that was pioneered by our founder, John F Goulding, of uniformly slitting and stretching the metal, micromesh produces no waste in its production. It’s sustainable and recyclable by design and as it’s manufactured from one piece of material there is nothing that can work lose and unravel.

The hole patterns created in its manufacture include the common diamond shape, as well as hexagonal which offers a good balance between the material and carrying capacity, and circle which is an economical alternative to perforated mesh. Each pattern can be supplied in 2D as flattened mesh or in a 3D raised structure. With our onsite tooling capabilities, we can also work with clients to develop bespoke mesh structures.

The aperture patterns and fine thickness of micromesh lends itself to a wide use of filtration applications within chemical processing, as it can permit light, air, heat and sound. This makes it suitable for use within filter bowls, support grids, filter cylinders, filter discs and copper micromesh offers great conductive performance, to name but a few.

Despite its small size, micromesh also retains qualities found in our regular expanded metal such as a high level of precision, flexibility and strength whilst being lightweight.

Materials used to manufacture micromesh include, but are not limited to:

- Nickel

- Stainless steel

- Copper

- Aluminium

- Platinum

- Titanium

Additional qualities which make micromesh suitable to the process industry include durability, corrosion protection and high conductivity.

What are the example applications of micromesh in process industries?

Let’s start with one of the most widely used example – filtration. As previously mentioned, the apertures in the micromesh allow a consistent flow of air, gaseous materials and liquid as well as light and sound which is of a particular benefit to process industries.

Micromesh is a highly versatile and adaptable filter material as it can be made available in coil or sheet form or cut to size for use in liquid and air filters. Our in-house capabilities enable us to press, roll form and weld the mesh into components for straining, retention and filtration.

Our micro expanded mesh can be layered into filter panels to capture dust and grease for both internal and external air filtration. And we supply made to order products with frames and backing meshes constructed in stainless steel, aluminium, galvanised steel and tinplate.

Micromesh in selective catalytic reduction

An increasingly common application of micromesh, especially where a lightweight, durable and cost-effective material is required, is as a catalyst in chemical processes.

Nitrogen oxides (NOx) are common air pollutants and through flue gas denitrification these harmful chemicals can be prevented from reaching the atmosphere.

The removal of NOx can be achieved through the denitrification process when using selective catalytic reduction (SCR). The straight and parallel apertures of the mesh provide a large gas-solid contact area and micromesh, which is economical in its design is a cost-effective alternative to wire mesh.

Stainless steel micromesh is used in the flow of catalytic material as it provides dust resistance, is highly durable to the intense attack of gases and when sprayed with a protection layer it offers increased temperature performance.

Micro expanded metal in the chloralkali process

Our micro expanded metal mesh is often found in electrolysis processes such as the production of chloralkali and hydrogen.

The reasons for using metal mesh are its ability to increase the amount of surface area which allows for more catalyst material to be used. With its evenly distributed apertures across the anode surface, micromesh provides optimal movement of solution and can increase current density and plating for better ion separation.

The fine thickness of our micromesh also reduces cell voltage, and it is durable to damage in the ion exchange of zero-gap environments.

Zero-gap environments are increasingly used as it means the whole membrane area is active, which offers energy savings and a longer life of the membrane.

Looking for more applications of our expanded metal mesh? Take a look at our articles on lightning strike protection, battery cells, fuel cells and filtration.

And if you’d like to explore micro expanded metal mesh applications in your chemical process please do get in touch, especially if you’re looking for highly conductive, lightweight, cost effective and sustainable alternatives.

GBP

GBP