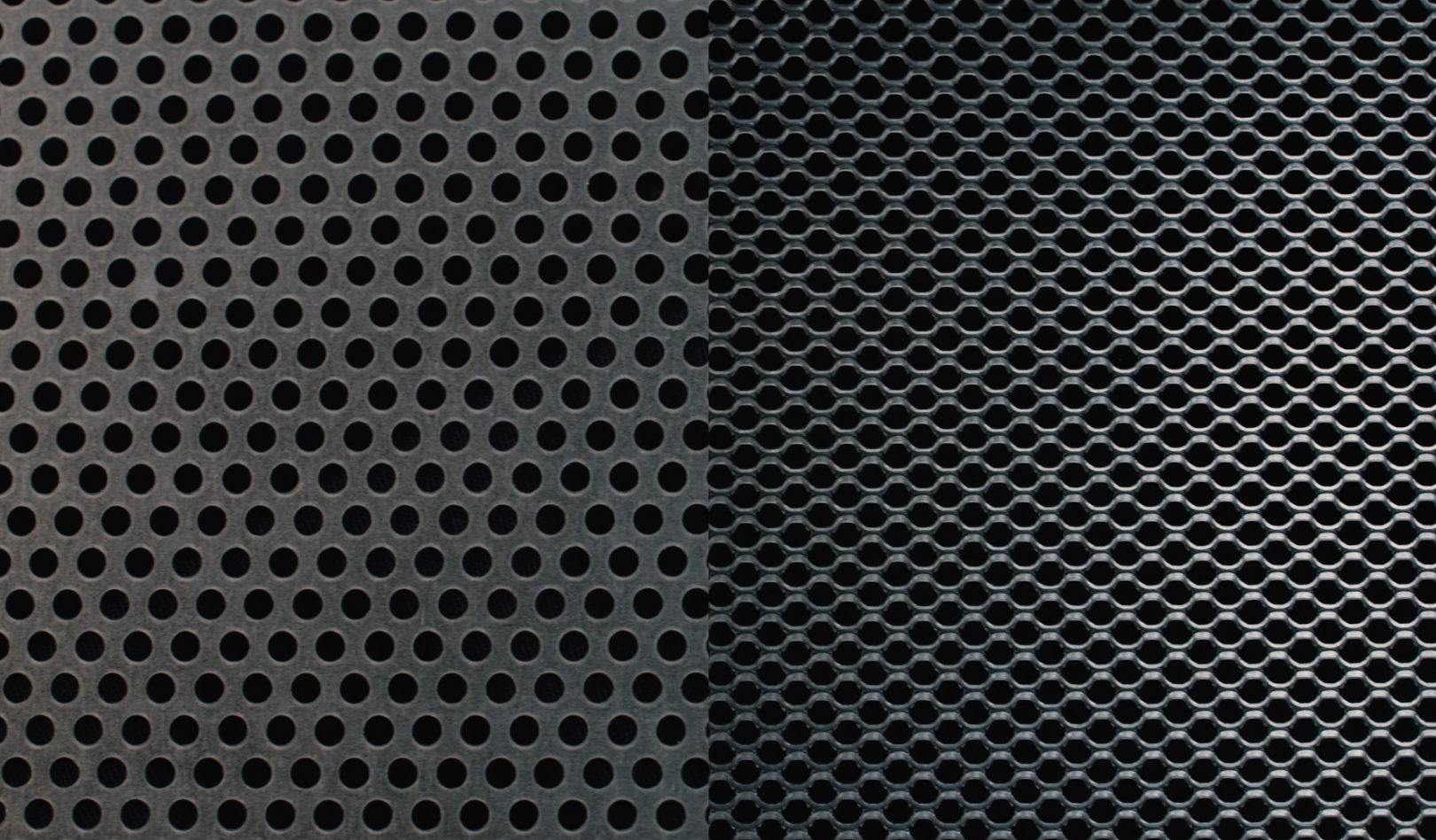

Expanded metal offers a viable, cost-effective alternative to perforated metal. From decorative screens for shop interiors, to industrial filters, to speaker grilles and architectural features, expanded metal can be used instead of perforated metal in most circumstances.

Expanded metal – including stainless steel mesh, mild steel mesh, aluminium mesh, and pre-galvanised steel mesh – has excellent filtration and ventilation properties and is highly effective in acoustic attenuation applications.

In addition, it can be used to control light and shade within buildings, and to create stunning visual effects – this makes expanded metal panels extremely popular with architects and interior designers.

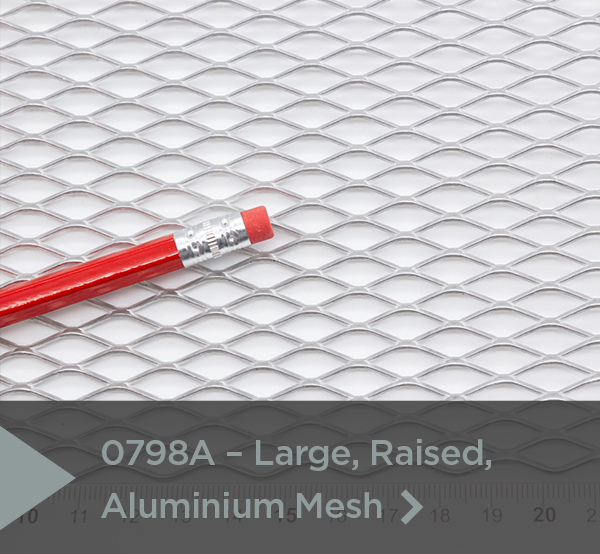

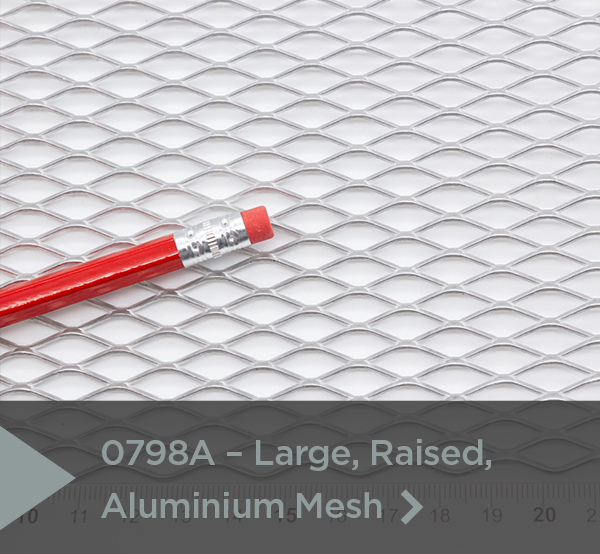

Plus, raised expanded metal offers superb grip, due to the ‘knuckles’ formed in the expanding process, so is often used in the manufacture of walkways, ramps, gantries, and stair treads. Again, in these applications expanded metal offers a robust and highly effective, anti-slip alternative to perforated metal plate flooring, decking or ramps.

Reduce waste by using expanded metal

In the manufacture of expanded metal, the expanding process entails slitting and stretching the material to create holes – which are usually diamond-shaped – rather than punching them out, as is the case when perforated metal is manufactured.

This means that raw material waste is minimal compared to the perforated metal manufacturing process – and up to 50 percent of raw material costs could be saved by swapping a perforated metal product to its expanded metal equivalent.

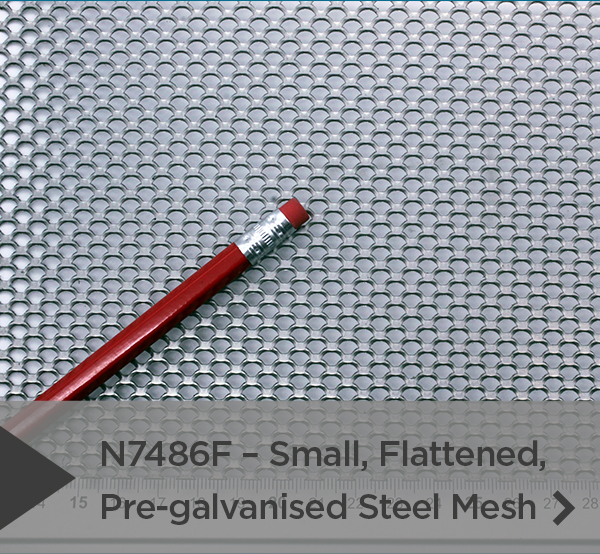

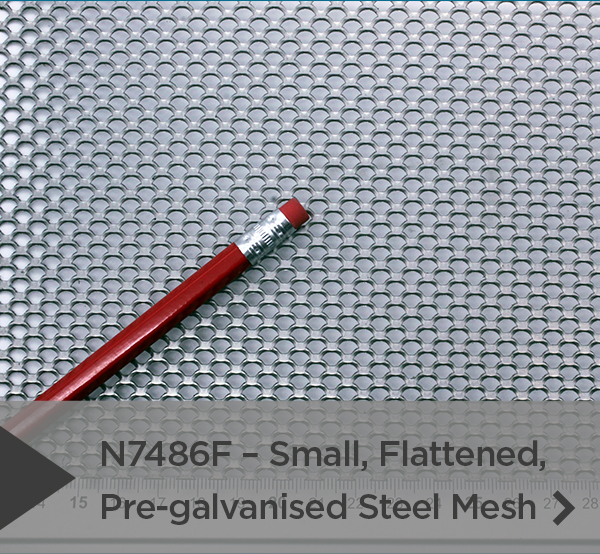

Our Experf mesh offers a very similar aesthetic and open area percentage to perforated metal – and has all the benefits of expanded metal. It is available in materials including stainless steel and pre-galvanised steel.

We also offer Micromesh, which is a fine expanded metal solution. Where high-value raw materials such as platinum, nickel or titanium are required – for instance in the manufacture of specialist components – the use of Micromesh can lead to significant cost savings compared to perforated metal.

Some common alternatives to perforated metal mesh

Looking for a cost-effective alternative to a perforated metal?

Explore our products for:

For more details on the benefits of expanded metal for applications such as filtration, architecture and acoustic attenuation, contact us.

GBP

GBP